Picture this: you’re at a bakery, ready to sell delicious cupcakes to your customers. But what if you run out of cupcakes unexpectedly? That’s where safety stock comes into play! So, what is safety stock in inventory management? Well, it’s like having a backup stash of cupcakes, just in case unexpected things happen. Let’s dive in and uncover the secrets of safety stock!

Imagine you’re planning a huge sleepover with your friends. You want to make sure you have enough snacks to last you through the night. The last thing you want is to run out of chips and cookies, right? Safety stock works the same way in inventory management. It’s the extra inventory you keep on hand to protect against unforeseen events, like surging customer demand or delayed shipments.

Why is safety stock important? Well, let’s say you run a popular ice cream shop during the summer. If a heatwave suddenly hits, you wouldn’t want to disappoint your customers by running out of ice cream, would you? Safety stock helps you maintain customer satisfaction by ensuring that you always have enough inventory to meet unexpected demands.

Now that we’ve dipped our toes into the sweet world of safety stock, let’s explore further and see how it can keep businesses running smoothly and customers happy as can be! So grab a cupcake and let’s dive in!

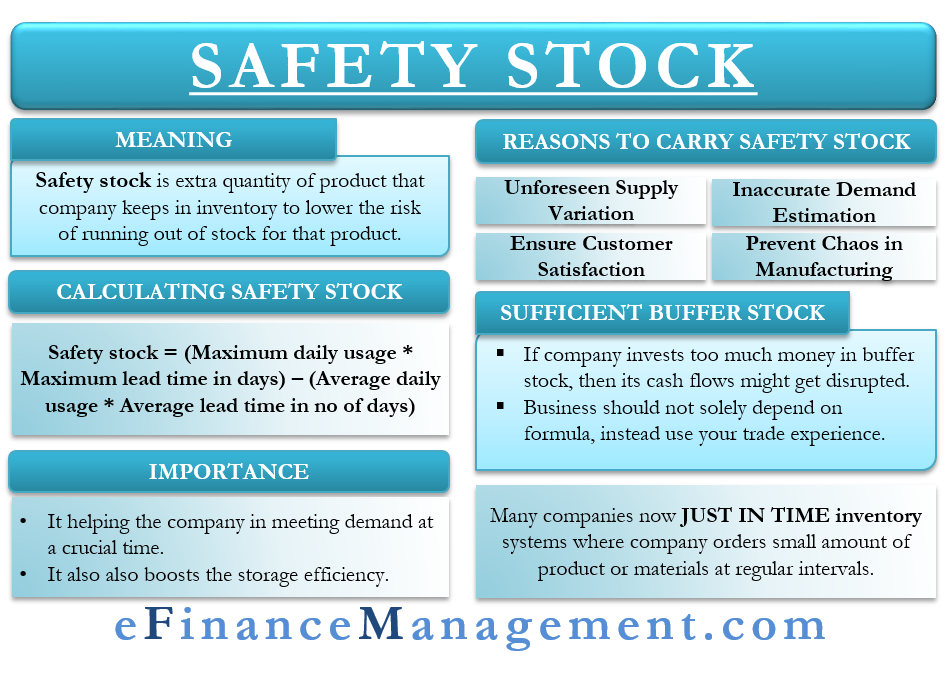

Safety stock in inventory management is a buffer inventory that serves as a protection against uncertainties in demand or supply. It helps ensure that there’s enough stock available to meet unexpected increases in demand or delays in supply. By maintaining safety stock, businesses can prevent stockouts and keep customers satisfied. It’s an essential aspect of inventory management that helps optimize operations and improve customer service.

What is Safety Stock in Inventory Management?

When it comes to managing inventory, one of the key concepts that businesses need to understand is safety stock. Safety stock refers to the extra inventory that a company holds beyond its average demand to mitigate the risks of stockouts. In other words, it acts as a buffer to ensure that a business can meet unexpected surges in demand, delays in supply, or variations in lead times.

In this article, we will explore the intricacies of safety stock in inventory management. We will delve into its importance, calculation methods, and best practices for setting appropriate safety stock levels. Let’s dive in and uncover the secrets to effective inventory management.

The Importance of Safety Stock

Safety stock plays a vital role in inventory management as it helps businesses protect against uncertainties and minimize the impact of supply chain disruptions. Here are three key reasons why safety stock is crucial for businesses:

1. Customer Satisfaction:

Safety stock ensures that businesses can meet customer demand even during unexpected situations. By having additional inventory on hand, companies can fulfill orders without delay, enhancing customer satisfaction levels and maintaining a positive brand image in the market.

2. Supply Chain Resilience:

Unforeseen events, such as natural disasters, transportation disruptions, or supplier issues, can cause delays in the supply of raw materials or finished products. Safety stock acts as a cushion to absorb these shocks and helps businesses maintain continuity in their operations.

3. Demand Variability:

Demand for products can be volatile and difficult to predict accurately. Safety stock accounts for demand fluctuations, seasonal trends, and the variance in customer orders. By having safety stock, businesses can respond smoothly to changes in demand and prevent stockouts.

How to Calculate Safety Stock?

Now that we understand the significance of safety stock, let’s explore the different methods to calculate it. Businesses use various approaches based on their specific requirements and the nature of their products. Here are three common methods for calculating safety stock:

1. Rule of Thumb:

The rule of thumb method suggests adding a fixed percentage to the average demand or sales forecast. This method is quick and straightforward to apply but may not be accurate for all businesses or products. It is ideal for businesses with stable demand patterns and minimal fluctuations.

2. Statistical Analysis:

Statistical analysis involves using historical sales data and statistical tools to calculate safety stock. Methods such as the standard deviation or the use of demand forecasting software help businesses forecast future demand variability. This method is suitable for companies with complex demand patterns and a large product portfolio.

3. Service Level Optimization:

The service level optimization method focuses on achieving a specific level of service to customers. Businesses analyze historical data and set a desired service level, such as ensuring on-time delivery for 95% of orders. Using advanced algorithms and mathematical models, safety stock levels are calculated to achieve the desired service level.

Best Practices for Setting Safety Stock Levels

To ensure effective inventory management, it is essential to set appropriate safety stock levels. Here are some best practices to consider:

1. Analyze Demand Patterns:

Thoroughly analyze historical sales data to identify trends, seasonal variations, and demand fluctuations. This analysis will help in understanding the demand patterns and setting accurate safety stock levels.

Subheading: Understanding Demand Patterns

By examining historical data, businesses can identify patterns in demand. This includes understanding the impact of seasons, holidays, and other events on customer purchasing behavior. Analyzing demand patterns allows businesses to adjust safety stock levels accordingly to ensure optimal inventory management.

2. Monitor Lead Times:

Keep track of the time it takes for suppliers to deliver goods and account for any variations in lead times. Longer lead times or delays require higher safety stock levels to avoid stockouts during the waiting period.

Subheading: The Impact of Lead Times on Safety Stock

Lead times refer to the time it takes to receive a product or material after placing an order. By understanding lead times, businesses can adjust safety stock levels to compensate for longer lead times and ensure that they have enough inventory to fulfill customer orders without delay.

3. Consistently Monitor Inventory Levels:

Regularly check inventory levels and adjust safety stock accordingly. This ensures that businesses have the right amount of buffer stock to meet unforeseen events and fluctuations in demand.

Subheading: Regular Inventory Monitoring

By monitoring inventory levels on a regular basis, businesses can identify any discrepancies, stockout risks, or potential excess stock. This allows for proactive inventory management and helps maintain optimal safety stock levels.

Conclusion

Safety stock is an integral part of effective inventory management. By having an appropriate buffer of inventory, businesses can overcome unforeseen challenges, meet customer demand, and maintain a resilient supply chain. Understanding demand patterns, monitoring lead times, and consistently reviewing inventory levels are crucial factors in determining optimal safety stock levels. By implementing these best practices, businesses can minimize stockouts and achieve seamless operations.

Key Takeaways: What is safety stock in inventory management?

- Safety stock is extra inventory kept as a buffer to protect against unexpected events or delays in the supply chain.

- It ensures that businesses have enough stock to meet customer demands even when faced with disruptions.

- Safety stock helps prevent stockouts and keeps customers satisfied.

- Calculating safety stock involves considering factors such as lead time, demand variability, and desired service level.

- Proper inventory management with safety stock can reduce the risk of stockouts and enhance overall customer experience.

Frequently Asked Questions

What is the purpose of safety stock in inventory management?

Safety stock is a buffer quantity of inventory that is held to protect against uncertainties in supply and demand. Its purpose is to ensure that there is enough stock on hand to meet customer demand, even during unexpected variations in supply or unpredicted increases in demand. Safety stock acts as a safety net to prevent stockouts and maintain customer satisfaction.

By having safety stock, businesses can minimize the risk of disruptions in their supply chain, such as delays from suppliers or unexpected spikes in customer demand. It provides a cushion that allows businesses to continue functioning smoothly, avoiding lost sales opportunities and potential customer dissatisfaction.

How is safety stock calculated?

The calculation of safety stock involves considering both demand variability and lead time variability. The formula typically used is:

Safety Stock = (Z-score * Standard Deviation of Demand during Lead Time) + Buffer Stock

The Z-score represents the number of standard deviations above the mean demand that a business wants to account for. It is often based on the desired service level, which is the probability of not experiencing stockouts. The higher the desired service level, the higher the Z-score and consequently, the higher the safety stock.

Buffer stock is an additional quantity that is added to the safety stock to provide extra protection in case of unexpected events, such as supplier delays or sudden surges in demand. The specific value of the buffer stock will depend on factors like the business’s risk tolerance and its historical data on disruptions.

What are the benefits of maintaining safety stock?

Maintaining safety stock offers several benefits to businesses:

1. Prevention of Stockouts: By having safety stock in place, businesses can avoid running out of inventory, ensuring they can consistently meet customer demand and maintain high levels of customer satisfaction.

2. Flexibility in the Supply Chain: Safety stock allows businesses to handle unexpected fluctuations in demand or disruptions in the supply chain without causing significant delays or a negative impact on customers.

3. Increased Productivity: With safety stock, businesses can focus on production or other areas without worrying about stockouts or supply chain disturbances. This can lead to increased productivity and overall efficiency.

What are the potential drawbacks of keeping safety stock?

While safety stock is beneficial, there are some potential drawbacks to consider:

1. Increased Inventory Costs: Maintaining safety stock means holding additional inventory, which comes with associated costs such as storage, handling, and insurance. These costs can add up and impact the overall profitability of the business.

2. Obsolete Inventory: If safety stock is not managed carefully, there is a risk of it becoming obsolete if it is not used within a reasonable period. This can lead to wasted resources and potential financial losses.

3. Limited Working Capital: Holding excess inventory as safety stock ties up working capital that could be used for other business needs, such as investing in growth opportunities or funding operational expenses.

How can businesses determine the optimal level of safety stock?

Determining the optimal level of safety stock requires careful analysis and consideration of various factors:

1. Historical Demand and Lead Time Data: Analyzing past demand patterns and lead times can provide insights into the variability and identify any trends or recurring patterns.

2. Market Conditions and Customer Demand: Understanding the market conditions and customer demand patterns can help businesses anticipate potential fluctuations and adjust the required safety stock accordingly.

3. Risk Assessment: Assessing the potential risks in the supply chain, such as supplier reliability or market volatility, can help businesses determine the level of safety stock needed to mitigate those risks.

4. Service Level Objectives: Defining the desired service level, which represents the probability of not experiencing stockouts, is crucial in determining the appropriate level of safety stock. It requires striking a balance between customer satisfaction, supply chain stability, and inventory costs.

By considering these factors and finding the right balance, businesses can determine the optimal level of safety stock that minimizes the risk of stockouts while optimizing inventory costs.

Calculating Safety Stock: Protecting Against Stock Outs

Summary

Safety stock is like having extra snacks in case your friends come over unexpectedly. It’s a cushion of inventory that businesses keep to make sure they don’t run out of products. By having safety stock, they can handle unexpected events like delays in shipping or sudden increases in demand. It’s kind of like playing it safe in case anything goes wrong.

To determine the right amount of safety stock, businesses need to consider factors like lead time, demand variability, and service level goals. They calculate it using fancy formulas, but the main goal is to strike a balance between not having too much excess inventory and avoiding stockouts. By having safety stock, businesses can keep their customers happy by always having products available when they need them.