Have you ever wondered how businesses effectively manage their product inventory? Well, you’ve come to the right place! In this article, we’ll dive into the world of inventory management and explore smart strategies that can help businesses keep track of their goods.

Managing product inventory is like playing a game of chess. It requires strategic thinking, careful planning, and efficient execution. But don’t worry, you don’t need to be a mastermind to do it well! With the right tools and techniques, anyone can become a pro at inventory management.

Whether you’re a small business owner looking to optimize your stock levels or just curious about how things work behind the scenes, this article will break down the process step by step. So, let’s jump right in and learn how to effectively manage product inventory!

- Start by conducting a thorough inventory audit to determine what products you have.

- Set realistic inventory goals based on demand and sales projections.

- Implement a reliable inventory management system that tracks stock levels and notifies you of low inventory.

- Optimize your storage space to ensure easy access and organization.

- Regularly review and update your inventory data to maintain accuracy.

Keeping your inventory in check is crucial for successful business operations. Follow this step-by-step guide to effectively manage your product inventory and streamline your operations. Start with an inventory audit, set goals, implement a management system, optimize storage, and maintain accurate data through regular reviews. By taking these steps, you’ll be able to keep track of your inventory and ensure you always have the right products in stock when you need them.

How to Effectively Manage Product Inventory

Welcome to our comprehensive guide on how to effectively manage product inventory. Whether you’re a small business owner or an inventory manager for a large retailer, having a solid inventory management system in place is essential. In this article, we will explore the key strategies and best practices for efficient inventory management, from optimizing stock levels to implementing effective tracking systems. So, let’s dive in and discover how to master the art of managing your product inventory effectively.

The Importance of Inventory Management

Effective inventory management is crucial for any business that deals with physical products. It ensures that you always have the right products in stock to meet customer demand, while also minimizing costs and maximizing profitability. By managing your inventory effectively, you can avoid overstocking or understocking, reduce the risk of stockouts, minimize holding and carrying costs, and improve customer satisfaction. Moreover, efficient inventory management helps streamline your supply chain, enhance order fulfillment processes, and enable better forecasting and decision-making. It’s not just a matter of having the right products; it’s about having them available at the right time and in the right quantities.

1. Consistently Monitor Inventory Levels

One of the foundational principles of effective inventory management is to regularly monitor your inventory levels. This involves keeping track of the quantity of each product on hand, the rate at which products are being sold or consumed, and the lead time for replenishment. By utilizing inventory management software or systems, you can automate this process and ensure real-time visibility into your inventory. This enables you to make data-driven decisions, such as when to reorder products, how much to reorder, and when to offer discounts or promotions to expedite sales. Regular monitoring also allows you to identify any discrepancies, such as theft, damages, or inaccuracies in stock counts, so you can quickly address them.

To effectively monitor inventory levels, consider setting up key performance indicators (KPIs) that align with your business goals and objectives. These KPIs may include metrics like stock turnover rate, sell-through rate, and days of inventory on hand. By regularly analyzing these metrics, you can identify trends, forecast future demand, and make informed decisions to optimize your inventory levels.

Benefits of Consistently Monitoring Inventory Levels

- Minimize the risk of stockouts and lost sales.

- Avoid overstocking and reduce carrying costs.

- Improve order fulfillment speed and accuracy.

- Optimize cash flow by avoiding excess tied-up capital.

- Enhance customer satisfaction and loyalty.

2. Implement Efficient Inventory Tracking Systems

Having an efficient inventory tracking system is essential for accurate and reliable inventory management. It involves assigning unique identifiers, such as barcodes or serial numbers, to each product to track its movement throughout the supply chain. This allows you to keep a record of when products enter and exit your inventory, ensuring accurate stock counts and enabling efficient order fulfillment.

There are various inventory tracking systems available, ranging from manual methods like Excel spreadsheets to advanced barcode scanning systems and radio frequency identification (RFID) technology. The choice of tracking system depends on the nature and scale of your business. While manual methods may suffice for small businesses with limited SKUs, larger enterprises may benefit from utilizing more sophisticated technology to streamline tracking processes and improve accuracy.

Efficient inventory tracking systems not only help prevent stock discrepancies and minimize errors but also enable better traceability and recall management, especially for businesses dealing with perishable or regulated products. Additionally, they allow you to gather valuable data on product movement patterns, sales trends, and customer preferences, which can inform your inventory purchasing decisions and marketing strategies.

Strategies for Effective Inventory Management

Now that we have covered the importance of inventory management and the key principles to follow, let’s explore some practical strategies for effectively managing your product inventory.

3. Optimize Stock Levels

Optimizing stock levels is a crucial aspect of inventory management. It involves finding the right balance between having enough inventory to meet customer demand without incurring excessive holding costs. While overstocking ties up capital and leads to increased carrying costs, understocking results in lost sales and dissatisfied customers.

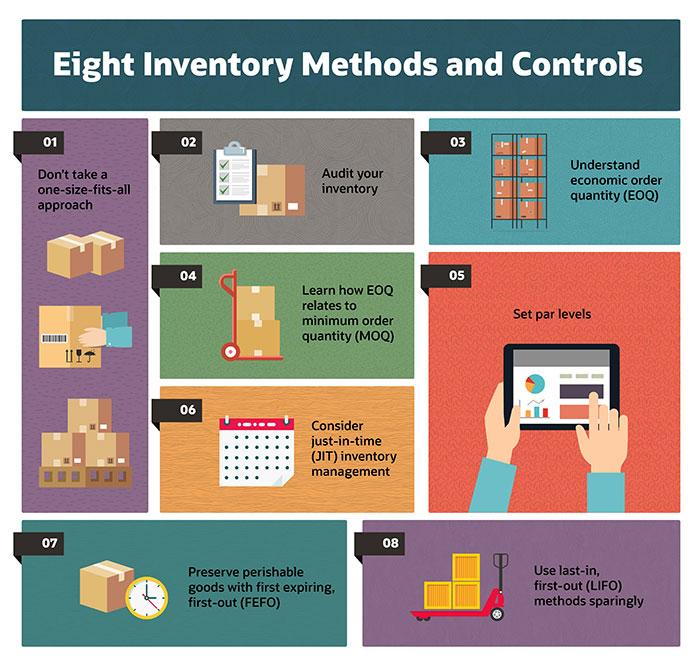

One approach to optimizing stock levels is implementing the Economic Order Quantity (EOQ) model. EOQ helps you determine the ideal order quantity that minimizes holding costs and ordering costs. By calculating the EOQ, taking into account factors like demand, lead time, and carrying costs, you can order products in quantities that minimize the overall cost of inventory, ensuring efficient inventory turnover.

Furthermore, employing just-in-time (JIT) inventory management can also contribute to optimizing stock levels. JIT focuses on receiving inventory only as needed and synchronizing it with production and sales cycles. By relying on real-time demand forecasting and maintaining strong relationships with reliable suppliers, JIT helps reduce excess inventory and associated costs while ensuring products are available when needed.

4. Categorize Inventory for Effective Management

Categorizing inventory is a valuable strategy for effective management, allowing you to prioritize and allocate resources based on the characteristics of different products. One popular categorization method is the ABC analysis, which classifies inventory into three categories: A, B, and C.

Category A represents high-value items that contribute a significant portion of your revenue, but typically constitute a small percentage of your overall inventory. These items require close monitoring and tighter control since stockouts or inaccuracies can have a substantial impact on your bottom line.

Category B includes medium-value items that contribute to your revenue but may have lower demand or lower profit margins compared to Category A items. Accordingly, these items should be managed with reasonable attention and tailored strategies to ensure optimal stock levels and customer satisfaction.

Category C comprises low-value items that have minimal impact on your revenue, yet often make up a significant portion of your inventory. These items may have sporadic demand or low sales frequency. As a result, they require less frequent monitoring and can be managed with more relaxed inventory control measures.

Key Takeaways: How to effectively manage product inventory?

- Regularly track and monitor stock levels to avoid overstocking or stockouts.

- Implement inventory management software to streamline operations and automate tasks.

- Categorize products and use clear labeling to easily locate items.

- Set up a reliable supplier network and establish reorder points to ensure timely replenishment.

- Analyze sales data and forecasting trends to make informed purchasing decisions.

Frequently Asked Questions

Are you struggling to effectively manage your product inventory? Don’t worry, we’ve got you covered. Check out these commonly asked questions to help you streamline your inventory management process.

Q1: How can I determine my optimal inventory levels?

When it comes to determining optimal inventory levels, you need to strike a balance between demand and cost. Start by analyzing your historical sales data and forecasting future demand. Consider factors like seasonality, trends, and promotions. Use inventory management software or spreadsheets to track inventory levels accurately.

Keep an eye on lead times, order frequency, and carrying costs. Set a reorder point based on your lead time and demand patterns. This will help you avoid stockouts while minimizing excessive inventory. Regularly review and adjust your inventory levels based on market trends and changes in customer demand.

Q2: How can I categorize my products to better manage inventory?

Categorizing your products can significantly improve inventory management. Start by analyzing your product portfolio and identifying common characteristics like product type, sales velocity, and profit margins. Classify your products into categories like fast-moving, slow-moving, low-profit, or high-profit.

Assigning ABC or XYZ rankings to your products can help prioritize your inventory management efforts. Allocate more resources to fast-moving or high-profit items and adopt different replenishment strategies for each category. Implementing proper categorization will help you optimize your inventory levels and reduce the risk of stockouts or overstocking.

Q3: How can I keep track of stock accurately?

Accurate stock tracking is crucial for effective inventory management. Start by implementing a barcode or RFID system to automate stock tracking. This will help minimize human errors and ensure real-time visibility of your inventory. Regularly conduct physical stock counts and reconcile them with your system records to identify and resolve any discrepancies.

Leverage technology and inventory management software to maintain an accurate stock count. Set up alerts for low stock levels or potential stockouts, enabling you to take timely actions like reordering or adjusting your production plans. By keeping track of stock accurately, you can prevent backorders, improve order fulfillment, and enhance overall customer satisfaction.

Q4: How can I optimize my warehouse layout for efficient inventory management?

An optimized warehouse layout can greatly enhance your inventory management process. Start by analyzing your order fulfillment flow and identify any bottlenecks or inefficiencies. Arrange your products based on their demand frequency, ensuring fast-moving items are easily accessible.

Implement proper bin labeling and barcode systems to streamline order picking and stock replenishment. Group similar products together, creating dedicated zones for different categories. Maximize vertical space and use efficient storage solutions like pallet racks or bins to maximize your warehouse capacity. Regularly review and optimize your layout based on changes in product lines or order patterns.

Q5: How can I effectively manage inventory across multiple sales channels?

Managing inventory across multiple sales channels can be complex but not impossible. Start by centralizing your inventory data using inventory management software. This will provide a holistic view of your stock across all channels. Ensure accurate real-time tracking and implement automatic stock adjustments.

Consider implementing a centralized order fulfillment system that integrates with all your sales channels. This will help streamline order processing and prevent overselling or stockouts. Regularly update your stock levels across all channels to avoid any discrepancies. By effectively managing inventory across multiple sales channels, you can provide a seamless and reliable shopping experience to all your customers.

Summary

Managing product inventory effectively involves keeping track of what you have and when to restock. It’s important to use technology to automate inventory tracking and make informed decisions. Regularly analyzing sales data helps identify trends and adjust inventory levels accordingly. Furthermore, optimizing storage space and implementing a first-in, first-out (FIFO) system can prevent stock from becoming obsolete. By following these steps, businesses can ensure that they have the right products at the right time, leading to satisfied customers and increased profits.